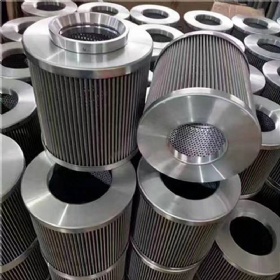

Stainless Steel Candle Filter Elements

Stainless Steel Candle Filter Elements is rolled by multi-layer (usually five layers) 316L or 304L stainless steel sintered wire mesh, sintered by high temperature vacuum, use argon arc or plasma welding to Cylinder.The size and distribution of the holes are adjusted by selecting the wire diameter, the mesh size and the weaving method of the wire mesh.

Raw Material wire mesh and Media

Material: SS304(L) SS316(L). Etc.Multi-layer Sintered wire mesh

standard five-layer sintered wire mesh

sintered square wire mesh ,

sintered Laminated plain Dutch woven wire mesh

sintered perforated and woven wire mesh

Size and parts information

Connection:Threaded Connection , 222, 220, 226, FlangeFiltration Rate:≥3μm

Parts:Stainless Steel Wire Mesh+ Stainless Steel Parts

Air Permeability:≥600 L / Dm² /Min

Wall Thickness:≥1.7mm

Color: Silver

Air Permeability: ≥600 L / dm² /Min

Length: ≤2000mm

Diameter: φ15-500mm

Working Temperature: ≤600℃

Working Pressure: ≤30MPa

Advantages:

- Good air permeability;- Excellent resistance to erosion, heat, pressure and abrasion;

- Uniform gas hole, high filtration rate;

- Large flow capacity;

- Reusing possible after ultrasonic weave, chemical reagent washing, free replacement.

Application:

-High polymer industry: synthetic, plastic or film production;-Chemical industry: petrochemical, petroleum or paint refining, etc.;

-Pharmaceutical and food industry: medicine/food refining or cycling;

-Mechanical and vessel industries: hydraulic machine/milling oil production, gas flow controlling;

-Gas industry: flow controlling;

-Air purification or water treatment: sterilization & filtration;

-Others: High temperature, high viscosity, high pressure.

Hebei Geluorui Filter Tech Co.,Ltd

Hebei Geluorui Filter Tech Co.,Ltd